DTF Printing Proficiency: Elevate Your Textile Creations with Direct-to-Film Innovation

DTF Printing Proficiency: Elevate Your Textile Creations with Direct-to-Film Innovation

Blog Article

Mastering DTF Printing: Idea for Achieving Vibrant and Resilient Prints

On the planet of textile printing, accomplishing vibrant and long lasting prints is a desirable skill that can raise the top quality of your output. Grasping DTF (Straight to Movie) printing requires a blend of technological knowledge, precision, and focus to detail. From choosing the appropriate materials to adjust print setups and improving post-printing finishing methods, there are numerous aspects that can influence the end result of your prints. Understanding just how to browse these ins and outs can make all the distinction in between a mediocre outcome and a truly outstanding one.

DTF Printing Basics

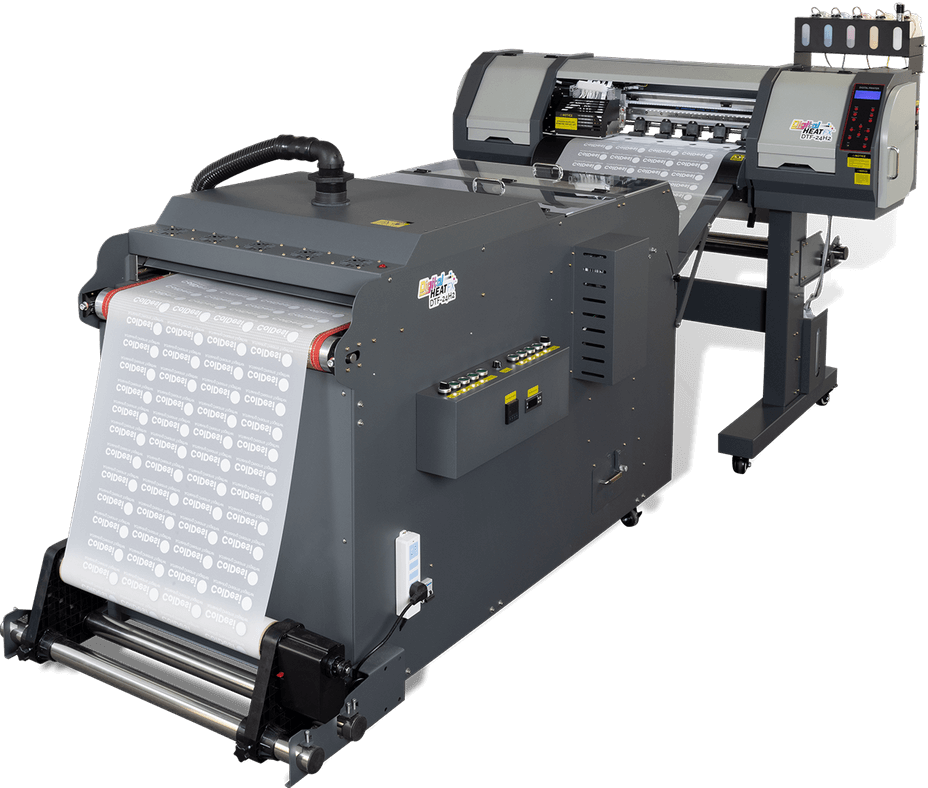

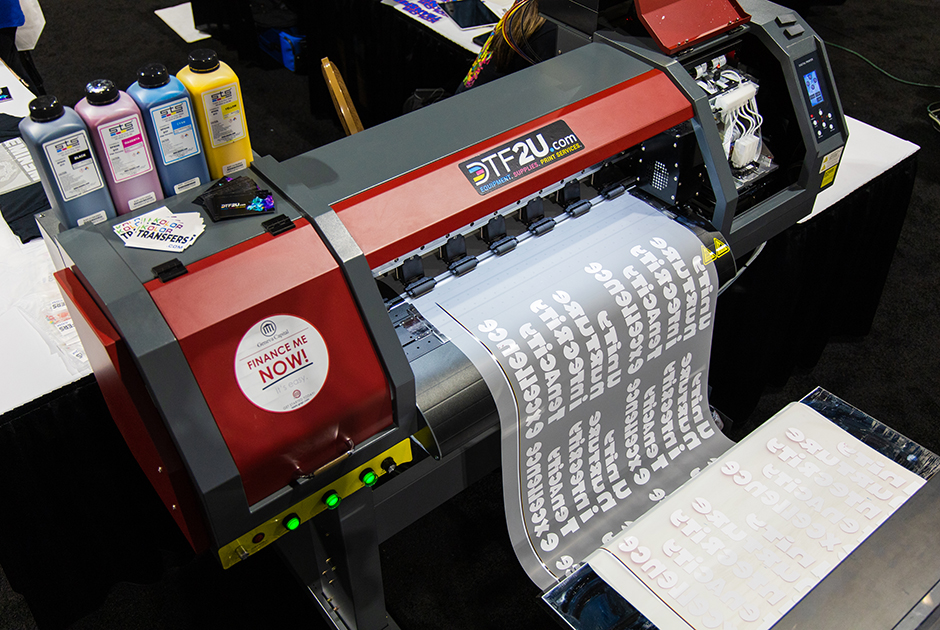

For those brand-new to the globe of fabric printing, comprehending the basics of DTF printing is crucial to understanding this cutting-edge method. Straight to Film (DTF) printing is a modern method that entails transferring styles from a special film onto various fabrics utilizing a warm press. Unlike conventional methods like screen printing, DTF offers benefits such as vivid shades, complex outlining, and the capability to print on diverse products like cotton, polyester, and blends.

The procedure begins by printing the design on a special DTF film using a compatible printer with CMYK or CMYKW ink sets. Once the layout is printed, it is after that treated with a warmth press to create a sturdy and long-lasting print. DTF printing is understood for its ability to replicate complex styles with high precision and shade precision, making it a prominent choice for services wanting to develop custom garments, promotional products, and extra.

Selecting the Right Products

The adhesive powder acts as a bonding representative in between the printed design and the fabric, so it must have strong attachment residential or commercial properties to make sure a lasting and resilient transfer. By carefully picking the right materials for DTF printing, printers can improve the high quality, vibrancy, and long life of their prints.

Maximizing Print Setups

When intending to achieve the finest outcomes in DTF printing, thorough attention to optimizing print settings is vital for ensuring accurate and top notch transfers onto textiles. One essential element to take into consideration when maximizing print setups is the resolution.

Another essential setup to enhance is the print rate. Discovering the ideal equilibrium in between rate redirected here and high here quality is crucial. While increasing the speed can enhance effectiveness, it may jeopardize the last print's quality and shade saturation. Explore various rates and observing the outcomes can assist establish the optimum setup for each and every print work - DTF Printing.

Moreover, adjust color profiles and guaranteeing appropriate color management are essential for attaining consistent and accurate shades throughout different prints. By calibrating shade setups and profiles, printers can reduce shade variances and create uniform outcomes, improving the general print quality and consumer satisfaction.

Preparing Art Work for DTF Printing

Convert the art work to CMYK color setting to make certain that the shades translate properly from display to print. Bear in mind to mirror the final style before publishing to make sure that it moves correctly onto the garment. By complying with these steps and paying close interest to the information, you can prepare art work that is enhanced for vibrant and sturdy DTF prints.

Post-Printing Finishing Methods

Applying effective post-printing completing methods is important to improving the resilience and aesthetic charm of DTF prints on fabrics. When the printing procedure is full, using warm to the published layout is vital.

When the film is removed, the print may need additional treating time to better establish the ink into the textile. This action assists enhance the washability and resilience of the print, guaranteeing it can stand up to numerous clean cycles without fading or splitting.

Additionally, cutting any excess movie around the layout can offer the last print a clean and expert look. Making the effort to properly end up DTF prints post-printing can substantially affect the general quality and visit long life of the textile style.

Conclusion

In conclusion, mastering DTF printing calls for a complete understanding of the essentials, picking appropriate products, maximizing print settings, preparing art work effectively, and making use of post-printing completing methods. By complying with these methods and tips, one can achieve long lasting and dynamic prints that satisfy their wanted high quality criteria. Regular practice and interest to information are important in accomplishing effective outcomes in DTF printing.

From selecting the best products to adjust print setups and developing post-printing finishing strategies, there are numerous variables that can affect the end result of your prints. Unlike traditional approaches like display printing, DTF provides advantages such as vivid shades, intricate describing, and the capacity to publish on varied materials like cotton, polyester, and blends.

Once the design is published, it is after that treated with a heat press to develop a lasting and resilient print.When aiming to accomplish the ideal results in DTF printing, careful attention to maximizing print settings is vital for making sure high-grade and precise transfers onto fabrics.In conclusion, understanding DTF printing requires an extensive understanding of the fundamentals, choosing suitable products, maximizing print settings, preparing art work successfully, and utilizing post-printing completing methods.

Report this page